re-locate a main bearing dowel - how to

Part number:

mbdr

Description:

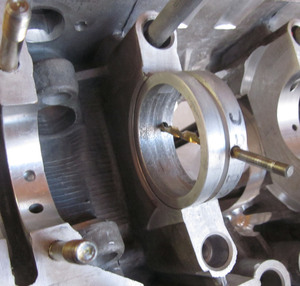

You've crawled a main bearing dowel and the std hole is junk.

Start by removing the pass through main block stud that is BELOW the dowel effected.

Clean the bearing's saddle (I use a dremel with a sandpaper attachment).

Grab a good used replacement bearing.

Drill STRAIGHT (with a .196 bit) through the std dowel location to the opposite side of the bearing. The .196 bit is smaller than the locate hole, but is the right size for the dowel.

This will leave a burr on the outside of the opposite side of the bearing.

Mark that side of the bearing with a felt marker or just leave the burr there.

Place the drilled bearing in the location you want it, being careful to center it and seat it, in the saddle.

Drill through the bearing into the block for the new dowel hole.

Clean and then clean a few more times and blow out the ports with compressed air.

Inspect and then clean again because you can't be too careful.

Place your new bearing in the saddle and mark a line across the top of it (in felt marker) for TDC so when you drop in the crank and see the line across the top, you'll know you're dead on.

Start by removing the pass through main block stud that is BELOW the dowel effected.

Clean the bearing's saddle (I use a dremel with a sandpaper attachment).

Grab a good used replacement bearing.

Drill STRAIGHT (with a .196 bit) through the std dowel location to the opposite side of the bearing. The .196 bit is smaller than the locate hole, but is the right size for the dowel.

This will leave a burr on the outside of the opposite side of the bearing.

Mark that side of the bearing with a felt marker or just leave the burr there.

Place the drilled bearing in the location you want it, being careful to center it and seat it, in the saddle.

Drill through the bearing into the block for the new dowel hole.

Clean and then clean a few more times and blow out the ports with compressed air.

Inspect and then clean again because you can't be too careful.

Place your new bearing in the saddle and mark a line across the top of it (in felt marker) for TDC so when you drop in the crank and see the line across the top, you'll know you're dead on.

We accept the following forms of payment: